The urgency to reach maximum efficiency is with a purpose as modern industrial technology demands it. Businesses must prioritize adaptable modular electrostatic discharge (ESD) workbench configuration as they serve as a solution to maximize efficiency. The fields provide adjustable functionality that handles the adaptable requirements of any developing workplace. This document checks the modular ESD workbench solutions by discussing ESD properties and cable management and with options in cold storage and the necessary equipment features.

Scalable Designs for Growing Facilities

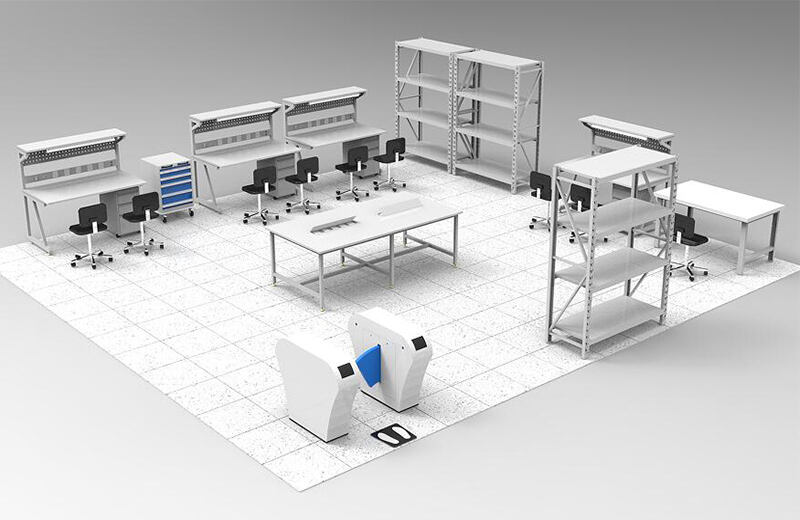

The main benefit of modular ESD workbenches is their ability to accommodate multiple scales in planning. The space requirements of a growing business tend to transform. The effectiveness of traditional workbenches diminishes because they do not provide necessary adaptability features for altering workplace requirements. The modular structure enables straightforward modifications which can be accomplished through expansions as well as reconfiguration processes.

Businesses can begin operations with a minimum arrangement and then extend their facilities as demands increase. Startup ventures along with small facilities do not need to allocate substantial infrastructure funds at the beginning. The business expansion requires its modules to integrate with additional components for expanding employee numbers or equipment or intensive workflows.

An advantage of modular designs is the ability to rearrange individual work areas. Production process changes and layout modifications at the facility become smooth through workstation modification instead of requiring total infrastructure replacement. The modular setup cuts down on operational outages which results in continuous workflow without interruptions for business productivity and efficiency.

Add-Ons: Drawers, Shelving, and Cable Management

The essential framework of a modular ESD workbench rests upon its skeletal structure but users can achieve personal workplace requirements by choosing from various available add-on components. Round-to-round essential add-ons for ESD workstations consist of built-in drawers together with shelving units and functional cable management systems.

Multiple drawer sizes and configurations serve as efficient storage tools which can separate materials according to equipment types. Specialized ESD drawers maintain the essential ESD protection of sensitive components by ensuring their proper storage method to prevent electrostatic discharge damage.

Shelving

A modular ESD workbench becomes more useful through the application of shelving units which serve as essential components. Shelving systems feature adjustable features which enable users to place bigger items or equipment under and above the main work area rather than using up essential workspace. The individual configuration system of shelves matches storage needs which produces a clean system-wide order and optimized workspace.

Multiple industrial and technical needs guide the customization of shelving systems which determine weight-bearing capacity and material resistance. A facility can both safeguard vital equipment and maximize its storage possibilities through the deployment of resilient ESD-safe shelves.

Cable Management

Managed cables represent an absolute requirement for operation facilities which contain many electronic devices. A lack of well-managed cables results in safety dangers together with equipment breakdowns which reduce industrial output and create higher maintenance expenses. The modular ESD workbenches feature sophisticated cable management methods which organize cables for safe storage.

These workbenches provide both built-in conduits along with tie-down points and cable trays which serve to secure all cables. The risk of cable disconnections becomes lower while maintenance tasks become simpler because of proper cable management. Cable management systems that integrate within ESD workbenches provide protection against sensitive components through the sustainable preservation of an ESD-safe environment.

Conclusion

Efficiency optimization in work places requires adaptable systems and equipment that also provide reliable execution. Facilities can increase their safety measures through modular ESD workbench setup as these platforms are compatible with changing business requirements. From scalable designs that support the essential add-ons such as drawer, cold bags and cable management, they increase the scope productivity, improve security, and ensure that the scope remains as efficient as possible.

By investing in a modular ESD workbench, businesses can ensure that they are well prepared to meet both current and future challenges, making this investment not only profitable, but also for long success.