The ongoing technological evolution and industrial processes require extraordinary measures to prevent electrostatic discharge (ESD) in different industrial sectors. Anti-static workstations act to reduce static electricity hazards thus protecting sensitive equipment and devices while securing operational safety at peak levels. The main application areas of anti-static workstations include the Electronics industry as one of the top beneficiaries alongside Medical Devices and Automotive sector among others. The analysis will showcase specific modifications Anti-static workstations deliver to various business sectors.

Electronics

The electronics industry stands as the number one sector Using anti-static workstations in its operations. Electrical components which include microchips together with integrated circuits and semiconductors are very sensitive when exposed to electrostatic discharge. A minor electrostatic discharge can produce major structural breakdowns that bring about system defects alongside decreased device performance until the device malfunctions completely.

This industry employs anti-static workstations as controlled environments that decrease the threat of ESD occurrences. A set of grounding devices including mats and wrist straps and ESD-safe tools compose the equipment available in these workstations. The path that anti-static workstations create enables the safe discharge of static electricity away from products to maintain their reliability and quality standards.

Medical Devices

Medical device manufacturing benefits crucially from anti-static workstations because they operate on highly important products. Pacemakers along with medical imaging devices and diagnostic equipment and other advanced electronic instruments in medical settings are highly sensitive to ESD. Such device malfunctions might create severe safety problems for patients.

Manufacturers operating in this sector implement anti-static workstations which follow regulations through custom-designed configurations to ensure procedural compliance with safety rules. Customized ESD protective systems integrate within these workstations to deliver safe electricity shielding for medical components through the entire manufacturing procedure. The production of dependable and safe medical equipment becomes possible through these procedures.

Automotive

The current wave of automobiles contains numerous electronic control systems which process both engine mechanics and security elements such as advanced safety systems and anti-lock brakes. Manufacturers within the automotive industry now utilize anti-static workstations as protective measures during electronic system production.

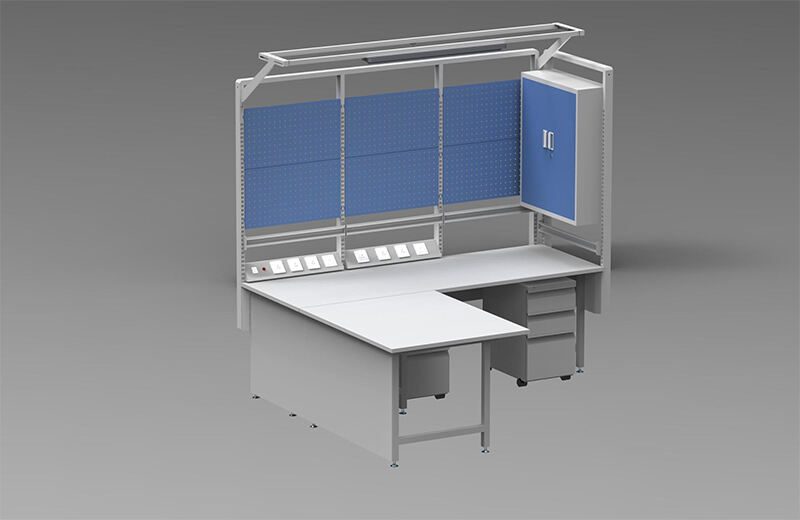

Automotive manufacturing industries use anti-static workstations to secure proper ESD-safe handling of essential elements including sensors and electronic control units (ECUs) as well as infotainment systems. The purpose of this protection method is to stop static charges from creating equipment failures that could endanger both performance and safety. Automotive manufacturers transform their anti-static workstations through dedicated shelves together with storage arrangements and ergonomic building components to both enhance production flow and maintain ESD protection.

Telecommunications

Network infrastructure together with smartphones and routers utilizes highly complex electronic components as the foundation of the telecommunications sector. These sensitive components face major danger from static electricity because it leads to data corruption and disruption along with hardware breakdowns.

Telecommunications organizations set up anti-static workstations which protect their electronic equipment from ESD damage while performing assembly and testing operations. The static-dissipative flooring and grounding systems plus ionizers combined give these workstations their static charge neutralization capabilities. These workstations can be customized to incorporate specific testing tools and equipment which results in improved safety for complete manufacturing operations.

Aerospace

Aerospace companies face demanding performance and safety standards among their industry sector. The aerospace industry follows strict rules for electronic systems since they operate under harsh operating environments. ESD creates severe failures within essential systems that forces manufacturers to use anti-static workstations for protection.

Anti-static workstations in aerospace manufacturing sector target the precise electronic components which form essential parts of avionics systems and navigation equipment and communication devices. The workstations include ESD-safe surfaces and grounding features that safeguard important parts during both assembly and testing along with maintenance procedures.

The systems include customization features which enableenan reorganization of the structure and integrated illumination for detailed work operations.

Industry-Specific Customization Examples

Each workplace installation of anti-static workstations requires unique individualized designs. Companies in each industry need distinctive customizations to achieve their functional and safety essentials. Industry-specific customization appears in various examples as follows:

Electronics: Workstations used in electronics involve built-in magnification lenses with task lighting systems needed for building tiny electronic components.

Medical Devices: The healthcare sector utilizes custom ESD-safe systems for sterile equipment storage together with surgical tools that adhere to strict medical standards.

Automotive: Work environments for automobiles contain ergonomic structures that use height-adjustable worktables which prioritize diverse workplace operations and staff comfort needs.

Telecommunications: Modular shelving systems along with compartmentalized units serve telecommunication needs for organizing electronic components while providing shielding against environmental threats.

Aerospace: Aerospace manufacturers require workstations designed for heavy-duty applications that combine resistance to demanding usage situations with ESD protection capabilities.

Anti-static workstations serve as essential equipment for different industries to remove the dangers associated with ESD. These workstations create a controlled environment which delivers customized solutions for industry needs thus ensuring the safety and reliability as well as longevity of electronic components to produce improved product performance and quality.