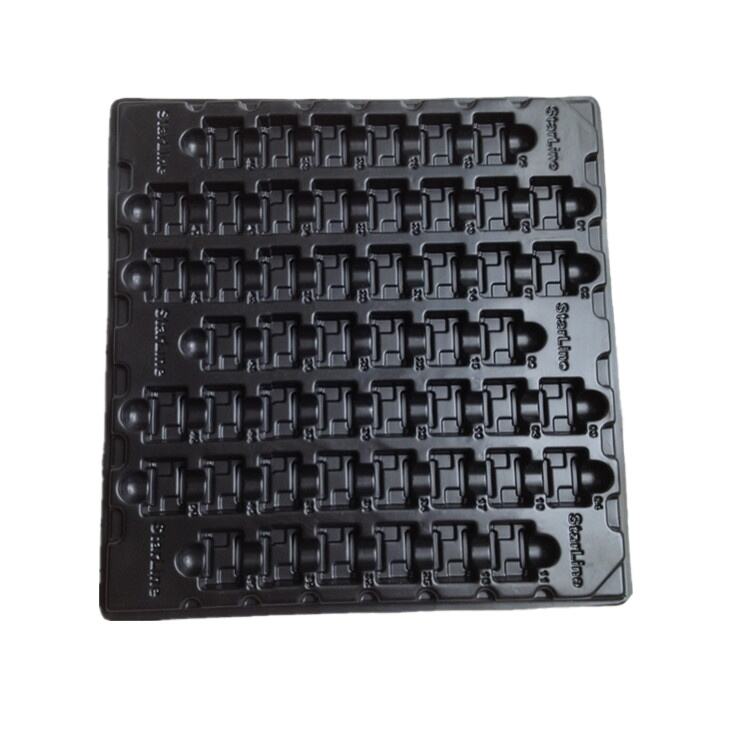

Custom Vacuum Forming ESD Plastic Blister ESD PCB Tray

General information about ESD Plastic Tray

ESD blister packing tray is made of PS as basic material, it can be made with only black color for conductive type, half-antistatic type etc. It has very good property and the conductive property will not be influenced by any humidity and temperature factors. It is permanent conductive.

Application of ESD Plastic Tray

l Disk industries

l Semiconductor industries

l Electronic product assembly and packaging

This material can be made into IC tray, LCD tray, Electronic Component tray, FPC tray etc. The surface resistance is very stable even after vacuum forming. It has very good property and the conductive property will not be influenced by any humidity and temperature factors.

Hot Sale Black PP Storage Plastic Tray With Divider Customized Accept

Technical parameters of ESD Plastic Tray

Property | Test Method | British System Value Unit | Intl. System Value Unit | Value Unit |

Basic Physical Property | ||||

Melt flow rate | ASTM D 1238 | 2.8 g/10 min | 2.8 g/10 min | 2.8 g/10 min |

Proportion | ASTM D 792 | 1.05 | 1.05 | 1.05 |

Extrusion molding data Mechanical Property | ||||

Tensile Strength | ASTM D 638 | 2600 psi | 18 Mpa | 183 kg/cm2 |

Breaking Strength | ASTM D 638 | 2400 psi | 17 Mpa | 169 kg/cm2 |

Breaking Elongation | ASTM D 638 | 40 % | 40 % | 40 % |

Tensile Modulus | ASTM D 790 | 230000 psi | 1600 Mpa | 16200 kg/cm2 |

Notch Impact Strength @23 oC | ASTM D 256 | 1.4 ft-lb/in | 75 J/m | 8 kg-cm/cm |

Thermal Property | ||||

Vicat Softening Point | ASTM D 1238 | 212 oF | 100 oC | 100 oC |

Heat Distortion Temperature @1.8MPa | ASTM D 648 | 198 oF | 92 oC | 92 oC |

Q1:How long you could prepare samples?

Ans:Normally 3days if we have the sample in hand.If customized one, about a week around.

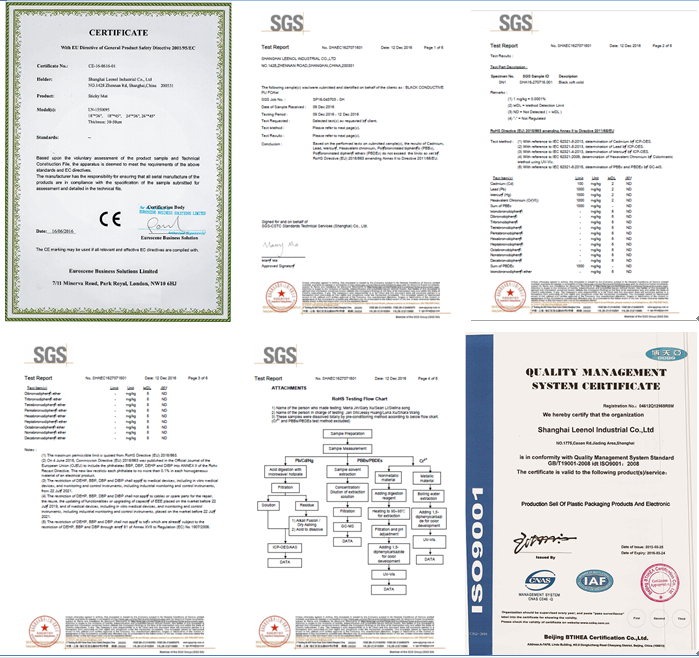

Q2:What advantage do you have?

Ans: 1.Professional engineer

2. Related responsible team

3.Strict and standard process control

4.Documents support on products

The LEENOL brand name is happy towards existing its own cutting edge Custom Vacuum Forming ESD Plastic Blister ESD PCB Tray, which is perfect for securely transferring and keeping a selection of digital circuit panels and elements.

Produced using first-class products which can be anti-static guarantee that no repaired fees can accumulation initially glimpse connected with the tray, which can or else damages fragile electronic devices. These products might likewise be light-weight however resilient and solid, guaranteeing that the tray can endure also the most difficult of handling problems.

Developed along with precision and focus on guarantee that it might fit a variety is broad of aspects, circuit panels, subsystems, and so on. Utilizing its own functions which are adjustable you will be specific it'll satisfy your precise specs when it comes to designs.

Anti-static residential or commercial homes, which will create it a choice is outstanding anyone dealing with delicate and unpleasant digital gadgets devices. The tray's location withstands discharge is electrostatic to ensure that it can safeguard your aspects coming from hurt caused through repaired.

This include is especially advantageous in avoiding launch is electrostatic ESD) phenomena that will ruin or even alter digital aspects.

Developed towards be stackable, along with interlacing ridges on the foundation, making it a simple job towards transfer and maintain. You can quickly pile trays which can be several stressing over all of them relocating or even moving far from one another.

Easy-clean style. The soft location of the tray implies it much a lot better to always keep and maintain cleanse therefore it is rapidly and totally wiped down, creating.

Do not be reluctant towards acquisition this Custom Vacuum Forming ESD Plastic Blister ESD PCB Tray coming from LEENOL for the very best in risk-free and protect electronic devices storages and transfer.