The many industries that include electronics manufacturing together with cleanroom operations must deal with electrostatic discharge (ESD) as a critical issue. Organizations require appropriate ESD protection systems to defend sensitive components al...

VIEW MORE

Many industries including those which handle sensitive electronic components need to prioritize Electrostatic Discharge controls because of its importance. Successful control of electrostatic discharge requires immediate implementation because it pro...

VIEW MORE

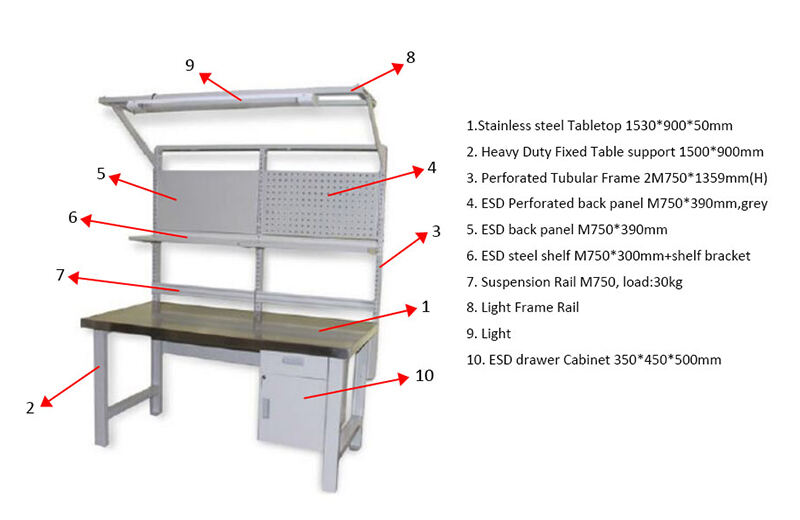

In various manufacturing and servicing environments the common threat comes from electrostatic discharge (ESD). A properly designed ESD-safe workstation serves as the cornerstone to defend delicate components from static-based destruction. Using an E...

VIEW MORE

The prevention of electrostatic discharge demands highest priority status from all facilities which service electronic parts during regular maintenance operations. A fatal undetectable event from electrostatic discharge renders delicate electronics u...

VIEW MORE

The electrical manufacturing sector depends on proper quality control methods along with strict adherence to regulations throughout its rapidly changing environment. The achievement of optimal standards depends heavily on Electrostatic Discharge (ESD...

VIEW MORE

Many electronic components, such as integrated circuits (ics) and transistors, are highly sensitive to static electricity. Static electricity may cause the tiny circuits inside the components to be broken down. For instance, the voltage of a common e...

VIEW MORE

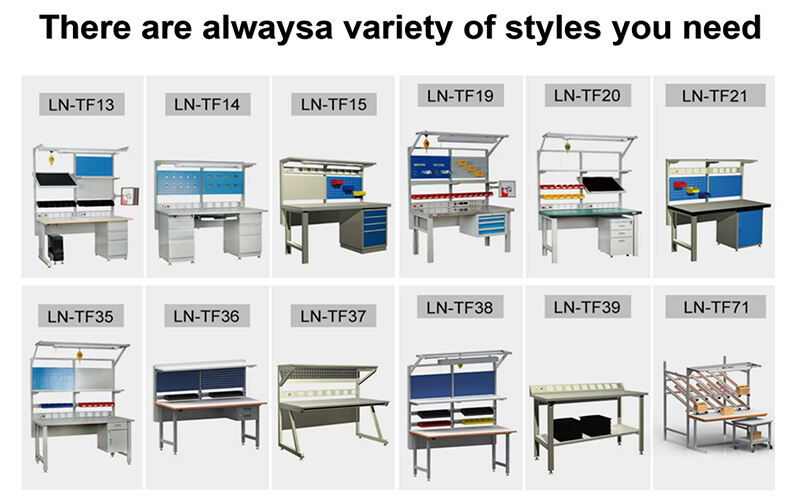

The electronics production industry advances speedily so ESD workstations have become essential implementation standards. The purpose of ESD workstations is to provide specialized environments that eliminate electrostatic discharges for protecting se...

VIEW MORE

Global growth towards technological advancement requires proper use of electrostatic discharge (ESD) workstation to prevent electrostatic damage. ESD workstation works as a tool required to deal with sensitive electronic components during production ...

VIEW MORE

Electrostatic Discharge (ESD) poses an essential risk in manufacturing and assembling operations because industrial workplaces handle electronics. The fast static charge discharges can detrimentally affect lightweight electronic components therefore ...

VIEW MORE

In the dynamic world of electronics assembly, maintaining a temperature and humidity-controlled environment is not just a luxury—it's a necessity. The ideal temperature range of 70-77°F and a relative humidity of 35-65% can significantly im...

VIEW MORE

The occurrence of Electrostatic Discharge (ESD) creates harm to electronic components that results in decreased product reliability and elevated product costs combined with unsatisfied customers. Your facility needs to perform ESD audits because this...

VIEW MORE

Any facility performing regular tasks with sensitive electronic components needs the appropriate choice of Electrostatic Discharge (ESD) workbench for protection. When applied within manufacturing facilities an ESD workbench functions as greater prot...

VIEW MORE